In 2019 W-Industries (“W”), a publicly traded US-based subsidiary of CSE-Global (CSYJY) comprised of 7 legal entities with over 1,000 employees across the globe, acquired Volta, an aACE customer of 12 years. As part of the acquisition, a senior auditor from one of the Big 4 accounting firms combed through their aACE 4 solution. When she said it was the “best solution she’d seen in 8 years on the job,” W’s leadership took notice. This remark – and seeing the difference in Volta’s efficiency for themselves after the acquisition – set them on a path toward bringing aACE to the rest of their enterprise.

In early March of 2020, just prior to the COVID outbreak, W-Industries’ CFO flew aACE Software President Michael Bethuy and Director of Product Development Brian Voll to Houston to make the big announcement in person: W-Industries was switching the entire company to aACE.

For many ERP companies, that would mark the end of the sales cycle. For aACEsoft and W-Industries, it was the beginning of a close collaborative relationship that would benefit both companies for years to come. That’s because while aACE 5, the then-current version of the solution, was very robust, it lacked a number of features that W would require for the project to be a success. Michael and Brian proposed an alternative that would guarantee the most rewarding possible outcome.

Rather than add individual features to aACE 5 on a custom basis, a more immediate but expensive option, the W-Industries management team agreed to sponsor a portion of the development of the upcoming version of the software, aACE 6. Though developing aACE 6 with a mind to meet more of W-Industries’ needs “out-of-the-box” would require more time before deployment, it was expected to be more cost-effective and ultimately more successful in the long run. A deal was struck, and work on aACE 6 began. The result now is an absolute win-win for both companies: a cost-effective, tailored ERP solution for the W team that they can fully support themselves, and a much improved product for the aACEsoft team that will continue to benefit all of our customers.

Volta and aACE: A Long History of Success

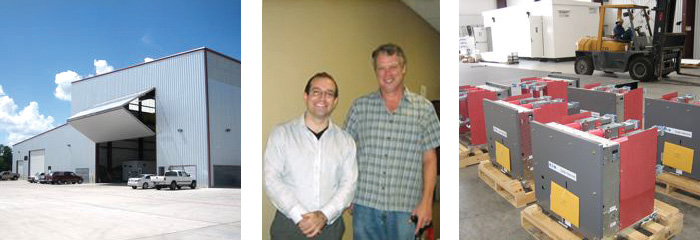

The seeds of what would become aACEsoft’s partnership with W-Industries were planted all the way back in the summer of 2008, when Volta first implemented aACE 3. Volta’s then-owner, Brad Davis, had previously searched unsuccessfully for a solution that would meet his company’s requirements. aACE’s flexibility, the ease with which it could be customized, and the aACEsoft team’s willingness to work closely with Volta to solve their workflow challenges made aACE the clear choice.

Like many small businesses, Volta didn’t have a big budget for service and customization. What they did have were talented employees and, now, a software package whose user-friendliness extended all the way under the hood where those employee talents could really shine. aACEsoft encourages customers to use in-house developers when possible in order to maximize their customization budgets; Volta gladly took advantage of aACE’s source-code accessibility to do just that.

After several years of collaborating with the aACEsoft team, Charles Hopper, an employee with an IT background who had started in their Shipping & Receiving department, began training. Charles soon became the resident aACE guru, molding the software around Volta’s unique workflows. “I did a couple of my own process automations with user scripts, such as a bar coding process that we were doing at the time,” Charles explains. “And generally I just kept bugging the manager of the system, which was Gretchen [de la Paz] at the time, to the extent that she decided to pull me into her department when an opening came about.”

Assessing and Reassessing

In 2010 Volta upgraded to aACE 4. Charles then spent the next decade continually customizing it alongside aACEsoft’s team to fit Volta like a glove. “A lot of the customizations that we’ve done have helped, but we couldn’t do that without the base software,” Charles has said about that endeavor. “We like how streamlined and how well-designed the interface is compared to other software that we’ve looked into in the past. We’ve resolved to stay with aACE because it’s just better. It’s a joy to develop for, too.”

In 2015, however, the relationship hit a snag. Volta was experiencing decreased performance from their aACE solution and decided that a switch to one of the big three ERP solutions was the answer. After investing six months – and six figures – into this new implementation and installing new servers, the Volta team realized they had made a mistake and the new system was not going to deliver the improvements they required. They abandoned the project. But not wanting the situation to be a total loss, they moved their aACE system to one of the newly-purchased servers and made a very welcome discovery: their performance problems were gone. With some increased horsepower, they realized that Volta could continue to flourish on aACE for many years to come.

Recommitted to using aACE for the foreseeable future, Volta invited Michael Bethuy to pay a visit to their office in Texas. Charles worked closely with aACE Software’s president, learning how to customize the solution even further by adding entirely new modules. “Once that was done, we were off to the races,” Charles says. “I’ve probably done about a dozen custom modules since, just filling in random gaps that were unique to our business. We had access to all of aACE’s internal workings, and we could just open up any of the out-of-the-box modules, copy and paste things, make adjustments, and layer in new versions and processes.”

Volta and W-Industries: An Exciting New Chapter

Volta had grown to over 100 full-time employees by the time W-Industries acquired them in 2019. The company’s various divisions do everything from heavy manufacturing to light manufacturing to distribution and service. It didn’t take long for W-Industries’ management to notice that the Volta division was significantly more efficient than their other divisions. For roughly the same amount of procurement work, for example, Volta only needed a single person using aACE compared to up to five full-time employees using other solutions. W’s management recognized the difference wasn’t the work – the difference was aACE.

At the time of the acquisition, Volta was still running on a heavily customized version of aACE 4. Although version 5 had been out for some time, the Volta team had chosen not to upgrade due to both the amount of re-customization that would have been required and the fact that aACE 4 was still working very well for them even though the software was nearly 10 years old. But when W-Industries’ leadership announced that they were transitioning the whole company to aACE, Michael and Brian saw a problem — and with it, an intriguing solution.

The aACEsoft development team was preparing to begin work on the next iteration of the software, aACE 6. Its release would mean that support for aACE 4 would officially cease. And while aACE 5 was more robust, it too lacked some of the features necessary for a company like W — besides, no one likes implementing a new technology only for its replacement to come along shortly thereafter. So Michael and Brian opted to approach the W team with a proposal that would provide a bigger win to both companies in the long run.

Essentially, the aACEsoft team would work with W to identify their precise requirements and, where possible, build them into aACE 6 as out-of-the-box features. W would sponsor that development as it occurred but the cost of features added to the “out-of-the-box” product would later be credited toward licensing fees.

This provided W-Industries with an unparalleled opportunity to steer the development of their chosen ERP solution while significantly minimizing their TCO (Total Cost of Ownership). Likewise, it gave the aACE Software team an unparalleled opportunity to take advantage of W’s real-world expertise while designing and developing features for the product. (Leveraging our customers’ expertise to develop software that actually works in the real-world has always been our secret sauce, which is reflected in our customer reviews and success stories.)

An Unprecedented Partnership

As aACE 6 development commenced, the two companies began a very close working relationship. Michael Bethuy moved from aACEsoft’s Idaho headquarters to Houston for nearly two years so that he could work onsite at the W-Industries office, with some of the people who would be using the software day in and day out. W situated Michael across the hall from Charles Hopper, who had now risen through the ranks at Volta to become W-Industries’ Enterprise Application Manager.

While in Texas, Michael worked with a team led by Charles that included W employees located right there in Houston as well as some scattered across the globe. This ensured that after the implementation, W would have in-house employees who could support the software without requiring expensive consulting contracts. This proved to be a valuable investment: In all of 2024, for example, W-Industries required fewer than twenty-five (25!) hours of support from aACEsoft, again significantly minimizing TCO.

In order to make the transition to aACE 6 go as smoothly as possible for the rest of W’s divisions, everyone agreed that Volta would upgrade to aACE 6 first. Volta’s users were already familiar with aACE and could help the development team identify and resolve beta testing issues. Volta became the first aACE customer to go live on a beta version of aACE 6 in June of 2022. After four more months of additional development, debugging, and optimization, W’s largest divisions went live on a pre-release version of aACE 6 in October of 2022.

aACE 6 was officially released to the public in March of 2023, and aACEsoft and W’s teams worked together that spring to bring the pre-release version W was using up to the official version of aACE 6.

Results

A “Single Source of Truth” for Multiple Entities

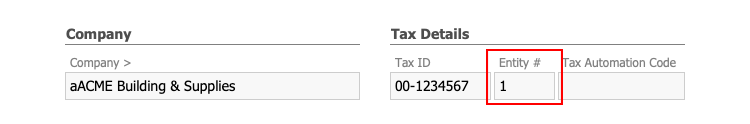

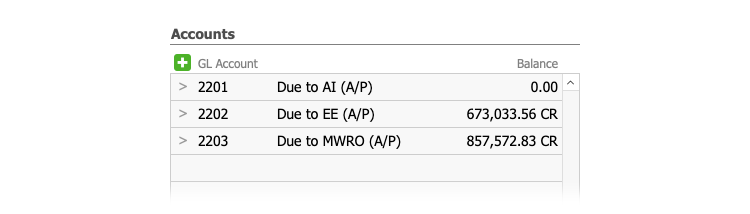

Prior to switching to aACE, W-Industries’ subsidiaries were being run on different software solutions. Further complicating matters, these various entities also have their own business units and sub-units. Fortunately, aACE’s multi-entity accounting features provided a strong foundation for managing all of these moving parts.

As part of the partnership between aACEsoft and W-Industries, the two teams worked together to ensure that aACE 6 would have the tools W needed to manage multiple entities within a single solution. “We’re now running 3 entities on aACE, including their business units and sub-units, without any customization to make that happen,” Charles says. “Offices in aACE have an entity assignment, so there are multiple offices that may be assigned to the same entity. And then we use departments in aACE to manage the business units. And again, there are some business units that exist across multiple entities, so we can report the general ledger split up by any of those metrics.”

This has allowed the W team to manage their complex organization in a single, comprehensive solution. “We don’t want to have another system out there that has to be the system of record” for a particular workflow, Charles explains. “We don’t want to have to keep two systems synchronized. Having aACE as a single source of truth for basically everything that could happen on a project has made things much easier to manage. Even with way more complicated ERP systems, most businesses will have something like Microsoft Project that’s not integrated with anything. So you’d have to have a scheduler or a team of people go in and manually push things into Microsoft Project.” With aACE, everything is live in the same system and there’s no need for an external file to be updated separately. As tasks are completed, aACE can update the associated records accordingly – no manual intervention needed.

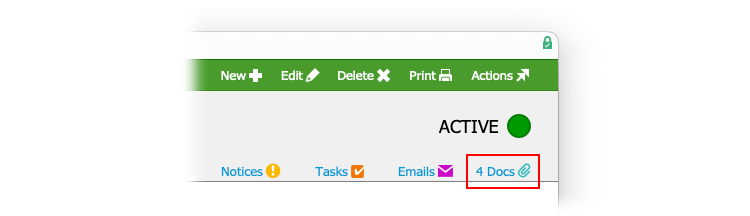

Access to Related Documents Right When and Where You Need Them

aACE even stores documents and attaches them to the relevant records, reducing the need for a separate system to manage files. “For journal entries, we used to have a folder saved out in a shared drive,” explains Rebecca Rigby, the Assistant Corporate Controller for W-Industries. “All of the supporting documents would be saved there, and we would have to manually get approvals for all of our entries. We’re audited every year, so we have to have all of that documentation easily available. And so we would keep all of that in a folder somewhere, and it just felt very disorganized.”

With aACE, they were able to clean up their filing system and eliminate that headache. “aACE has that nifty Docs feature on nearly every record available, and so now we just create a journal entry, add the support document to it, and then have someone else post it. And that’s been sufficient for us,” Rebecca says. She also notes that it’s made a difference outside of the Accounting department, too. “Project managers can save all of their purchase orders and any budgeting information or other helpful information right in the project,” she explains. “Having the invoices for purchases attached right there to the record in aACE makes it so easy. That whole Documents feature has greatly helped us.”

Handling Transactions Between Entities is a Breeze

aACE has also made transactions between these various entities a breeze. “It used to be that for every single month, we would run reports of what the balances were for each entity,” Rebecca recalls. They would manually comb through each report, looking for anything amiss. “We’d have to figure out which transactions were causing imbalances and then manually book journal entries into each of the entities,” she continues. They would then have to run the reports again, restarting the process as many times as it took until everything balanced perfectly.

“With aACE, partially because we’re all on the same system and partially because aACE books all the entries for us, we don’t have to do that process at all anymore,” Rebecca explains. “aACE allows us to create entries on each other’s books pretty seamlessly.”

A Solution that Puts User Experience First

No matter how many bells and whistles an accounting solution might have, at the end of the day it’s only useful if it’s actually being used. This made their previous software solution a problem for W’s Texas division, whose employees sometimes struggled to interact with the software and consequently began operating outside of it.

“The biggest issue [with the old system] was that it wasn’t user-friendly,” explains Rebecca. “So people didn’t really use the system because it wasn’t pretty, and it wasn’t entirely intuitive.” This was an especially big problem for project managers, who had the data they needed but didn’t always know how to access it. “I believe most of them were probably keeping spreadsheets on the side,” Rebecca explains. “Project managers would keep lists of POs they had asked Purchasing to issue to different vendors, for example. They would keep track in their own way of when things were received and estimate when those costs would hit the job, but it was all an estimation. Now with aACE we can look in the system and see exactly where things are at.”

Spend Less Time Following Up

aACE also cut down on the amount of following-up each team member needed to do, because the data they need is readily available at their fingertips. “There was a lot of chasing down information” in their previous solution, Rebecca confirms. “We still had the WIP file, so that would show them what their cost was as of a certain point in time, but there was no detail for that – nothing to show whether it was time costs or POs or what have you. So we would have to go chase down those details, and it was time-consuming.”

“I used to get emails all the time, asking for cost reports and whatnot,” Rebecca continues. “A lot of that can just be pulled straight from aACE now, so that’s been really helpful.” And when she does get questions, they tend to focus on specific pieces of data, reflecting the fact that staff members have been using aACE. “The questions that I get now are more, ‘Why doesn’t aACE show what you’re showing?’ Which is a much better question than just, ‘Tell me what you have.’ And I get that from people that I didn’t expect to take to the software at all. It seems like now that they understand the purpose, they really like it.”

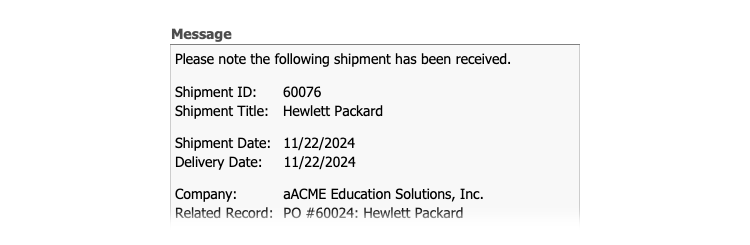

Now instead of spending time sending and receiving updates on projects, W’s staff can simply update a tracking status here, add a comment there, or send a notice to keep everyone up to speed and hand off to-dos to other team members. “We really utilize the Tasks function in aACE to let each other know when things are ready for review or something needs to be looked into or whatnot,” Rebecca says. “That’s really helped us cut down on our Teams and email traffic.”

A Streamlined Process for Onboarding New Hires

aACE’s ease of use also makes onboarding new employees much simpler. “It’s very intuitive, very user-friendly, and very easy to train other people on how to use,” she says. “And I really appreciate that every screen basically functions the same way. If you learn one, you’ve learned them all.”

Looking back, it can be hard to imagine how they ever got along without aACE. “I have to log into our old system periodically to look at historical transactions,” Rebecca says, “And sometimes I can’t for the life of me figure out how that system works or where I can go to find invoicing information. It’s bad. I was in that system for years before we switched to aACE. We’ve been out of it for two years now and I have a hard time remembering how to find things. It’s a night and day difference.”

More Efficient and Accurate Accounting

Because each of W’s subsidiaries used their own software before the switch to aACE, they each needed their own separate accounting departments. As each division moves to aACE, W’s leadership is finding that they can consolidate certain functions under one roof.

W’s Louisiana division, for example, now has many of their accounting functions taken care of by Rebecca and her team at W’s Texas headquarters. This has allowed them to repurpose their employees’ time for other, higher-value tasks. Ashley Latiolais, former Controller and now the OTC Director at W-Industries Louisiana, saw her role change as a result of the aACE implementation. She states that she did “every aspect of accounting, every function” before switching to aACE. “I did A/P, A/R, every journal entry that was recorded, bank reconciliations – everything. Once we went live on aACE, that role was eliminated. We had an accounting team for our W-Texas location who was already doing all of that, and because we were now under one system they were able to absorb that role.” Ashley and one other employee were able to shift to higher-value roles within the Louisiana branch; a third position was able to be eliminated when the person who’d held it left the company.

Ashley used to manage the bulk of the Louisiana office’s accounting workflows in Peachtree. She describes it as a tedious and error-prone experience. “We used to use Peachtree for invoicing, posting costs to jobs, accounts payable, journal entry recording… basically, all of our financial reporting for the Louisiana operation came from Peachtree,” she says.” There were some limitations there. For example, we could create an invoice on any project without checking whether or not the relevant costs had been recorded.” If a cost had been missed, Ashley’s team wouldn’t know until they closed the job – and then they had to work backwards to research whether that cost had been coded to the wrong job or simply hadn’t been applied at all.

And sometimes the mistake wouldn’t be caught even when the job was closed. “That was one of the major improvements when we moved to aACE,” Ashley explains. “What we would have to do in Peachtree was look at a job report at the end of every month. We’d have to look at each job and examine the costs, the billing, the accrued revenue, and so forth. We have estimated margins for each project, so if those margins weren’t in line with what we were seeing, we would have to drill down on them to see if there were costs missing, or if the costs were too high was it because something had been applied to the wrong job, and those kinds of things.”

“It’s also helped to eliminate the duplicate billings that used to happen when we didn’t have to have the cost [tied to a job before invoicing],” she continues. “In Peachtree sometimes a project manager or biller would make a mistake and accidentally bill an invoice twice. There was no way for us to catch that without manually checking every single invoice before sending it. In aACE, because we have to pull the cost from a specific ticket or purchase order, if it’s already been invoiced we don’t see it anymore.”

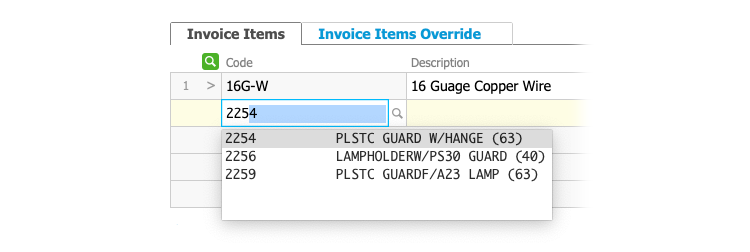

Faster Invoicing with Data from Inventory Management Modules

The Louisiana office has also recently implemented aACE’s robust inventory management tools, which Ashley says has also helped to ensure that invoices are accurate. “Now we actually have inventory in our system that we can use to pull in the costs of items when we invoice,” she explains. “That wasn’t an option in Peachtree. We used to have a manual process that we had to follow when we were creating invoices. Whenever a ticket came in for billing we would not only have to invoice it, but at the same time we’d have to manually create a journal entry based on the cost and post that to the job.”

Automating the office’s inventory has been a big time-saver. “Inventory would probably take a good two days at the end of each month,” Ashley recalls. “We’d have to calculate all the material costs for the month and then make the entry. With aACE it’s no longer a manual process. That’s a big change, and it’s something that’s always been a goal.”

Comprehensive Reporting Tools Cut Reporting Time in Half

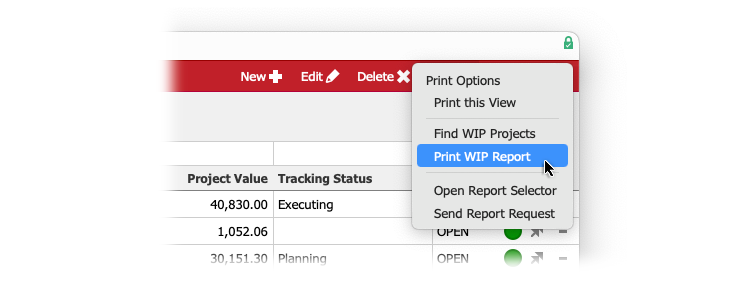

And over at W’s Texas division, aACE’s comprehensive reporting tools has made life easier for the team that’s now performing some of W-Louisiana’s accounting functions in addition to their own. “We’re actually getting the data for our WIP report directly out of aACE now,” Rebecca notes. “Before, I would have to download a report showing the costs by job and then download a different report showing the billings by job. Then I’d have to go back and tie that to the General Ledger, because the sources for those items were not the GL. If anything was off, it was hard to track down the source of the problem because the GL in our old solution didn’t house the job number related to those transactions. And so trying to figure out where those variances were was very challenging.”

“With aACE,” she continues, “All of that data is housed in the GL, which makes it very easy. It used to take a full day to build those WIP reports. Now it’s just a matter of downloading a report, and the data populates. It still takes a little bit, but we’ve gone from an entire business day down to half a day at most.” That 50% reduction in the time it takes to build a single report gives Rebecca and her team hours back in which to focus on higher-value work.

Increased Visibility, Robust Permissions Control

Before aACE, some of W’s subsidiaries struggled with a lack of controls in their software. “There were some weird things with receiving material where the Shipping & Receiving team could potentially go into the system and mess with things that they weren’t supposed to be able to access,” Charles says. “The access model was that bad.”

On the other end of the spectrum, some users had no access to the data they needed at all. “Most people in the company who weren’t directly involved in transactions had no visibility into the system,” Charles explains. “There were massive amounts of people who just had to wait for someone else to log in and pull data for them.” This resulted in a lot of wasted time, both for the non-users who had to wait around for someone to access the system on their behalf and the users who had to stop their own tasks to assist their colleagues.

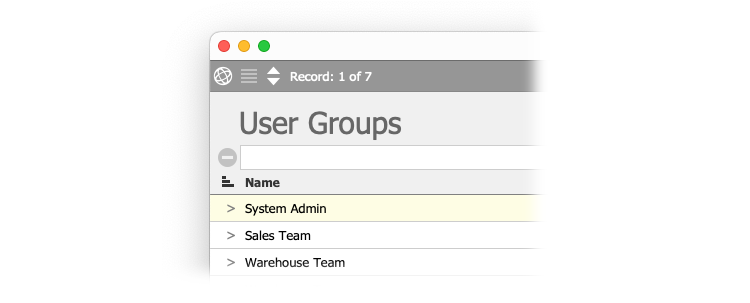

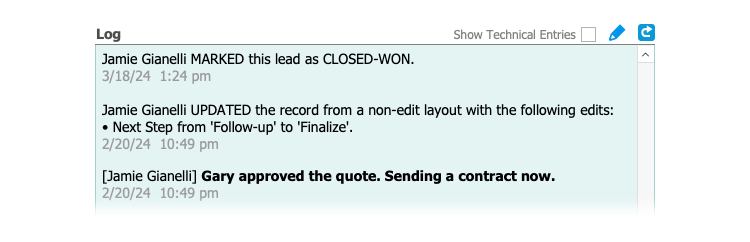

aACE’s sophisticated user privilege tools make it easy to ensure that everyone has access to the data they need, while isolating specific groups from areas of the solution that don’t pertain to them. And aACE’s advanced logging features give W’s leadership the peace of mind that comes from knowing they can see exactly who made important changes to records in the system. “Now that people can get their own data, practically every transaction takes a lot less time,” Charles says. “And that’s even with our company growing and things becoming more complex than they were three years ago.”

Rebecca notes that aACE’s ease of customization enabled W to control their users’ privileges much more effectively than they did in their previous solution: “I think that because we have such close access to the programming and development side of aACE, we were able to tailor those permissions according to what our teams need much more closely than we were able to in our previous solution. That’s a wonderful thing. It’s definitely an improvement.”

Who Did What and When: Approvals and Audit Trails

Ashley also appreciates aACE’s robust security tools. “One of the things I like a lot with aACE is the approval functions,” she says. “We have to have approvals for every single invoice that we process from the project manager, for certain milestones and billings and things like that. I love the fact that we can just forward the approval to aACE via email and it’s automatically attached to the invoice and the job. Everything’s there.”

This also creates an easily-accessible audit trail. “Audits are a huge, huge thing in our department; we have outside auditors that come in for two weeks toward the end of every year, and then again for two weeks after we close the year in March,” Ashley says. “And we used to have to sit there and go through stacks and stacks of invoices, pull all the invoices for them, and pull all the approvals and supporting documents. Now we just give them a login to our aACE system and they have everything they need. That right there is huge.”

A Custom Solution for Long-Term Scheduling

“One thing we do differently than a lot of other organizations is that our work spans multiple months, sometimes even years,” Charles explains. “It’s not a sales order that gets booked and then shipped within a day or a week. It’s a massive scope of work, worth hundreds of thousands to hundreds of millions of dollars.” Just estimating each project is a monumental effort, and when W wins a bid, they then have to book all of the necessary resources to execute it.

“Getting all of that to work in any system is difficult,” Charles says. “And yet, we were able to take a system that wasn’t necessarily designed specifically to do all of that and make it work for us without much effort.” He credits aACE’s inherent flexibility with enabling that tailored fit, adding that the customized portions of the solution were easy to integrate throughout the system. “We wound up with some really powerful tools related to scheduling that link everything together across the projects, purchase orders, jobs, and other things that we’re using that are all out-of-the-box. It gives us a complete picture that fits the business model that we have.”

And when things change, aACE makes it easy to update all of the related records. “We can have a customer issue a PO, and then there can end up being 50 change orders to that job,” Ashley explains. “And every time they send one, we can just update the value. The project management team takes care of updating the project, and automatically the job and the milestones and the dates and the schedule all have that data. Every change can be documented, and we can put quite a bit of information in there. Whereas in Peachtree, we just had job folders and paper everywhere. So that was a huge, huge improvement for us.”

In Their Own Words

Here’s what Charles Hopper has to say about W’s aACE 6 implementation:

“Flexibility is the most powerful feature for supporting scale. For us, scaling means organic growth into other businesses just as much as organic growth into the existing business. With new businesses come new challenges, and with new challenges, systems that are inflexible fail. And then instead of fixing that system you’re stuck either abandoning ship and switching software every few years, which is something that big companies often do, or supplementing that original solution with dozens of other systems. These are things I would really like to avoid, and throughout my career working with aACE, we’ve been able to successfully do that just by having such transparent access to the source code and to the team of developers that can help us through some of these challenges.

“It’s very cost-effective, both from a standpoint of licensing for FileMaker and licensing for aACE. Some solutions cost millions of dollars, and that’s a barrier we would have to overcome before we could grow. With aACE, we just understand that the cost is X amount per user. And it’s not something that changes dramatically year to year.

“I essentially helped co-develop aACE 6, working 35 to 40 hours per week with the aACEsoft team for two years straight. It’s a very intimate relationship. I don’t think we could have seen that same thing happen with other software even working with consultants, let alone the actual software vendors themselves. Usually there’s millions of dollars’ worth of distance between the people who want something done versus the people who know how to do it, and we’ve had the privilege of not having to deal with that problem. And the aACEsoft team is very professional. They have people who are just really, really good at what they do from a programming standpoint, understanding problems and then developing unique solutions to them. As a manager I deal with hiring and firing people who do the job these folks do, and I’d be lucky if I could get just one person like [the aACEsoft team has].”

Interested in learning more about what aACE can do for your business? Read our Feature Highlights to see how aACE can help you take your operations to the next level.