Within every business, there are processes that require repetitive workflows. If you have to enter this information into your solution manually every time you use the process, it can be inefficient and distracting from your business goals and growth.

aACE’s task groups solve this problem. When you create a new aACE task group, you can enter each of your process’s steps as individual tasks. aACE can then auto-generate these task groups on your orders.

Interface Spotlight

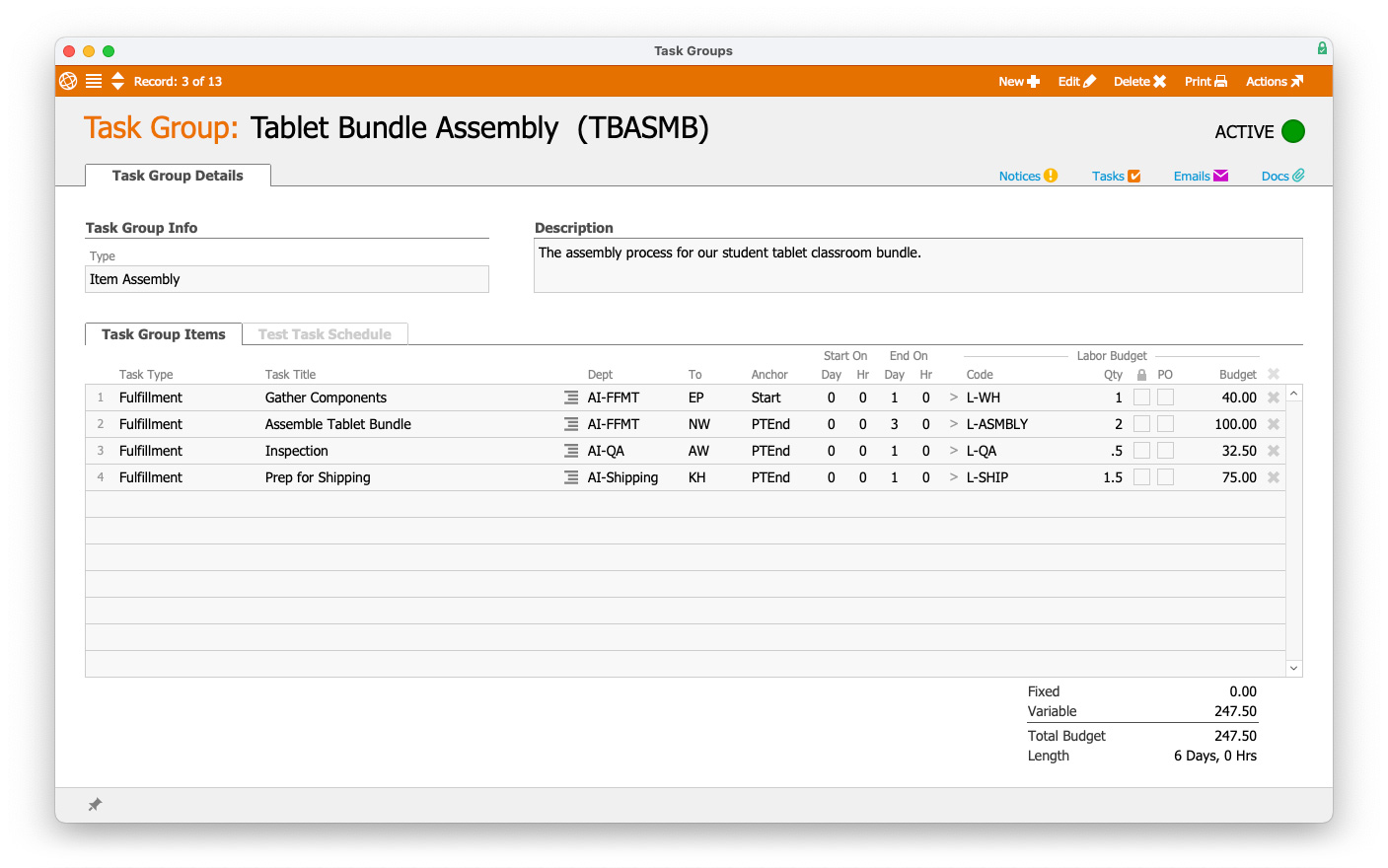

Tasks within a task group can be individualized based on your process’s requirements. You can assign departments, team members, and inventory items to each task. Additionally, you can configure the estimated start and end times for each step of your process, which allows aACE to track progress and the timeline of the process.

When your task group is complete and activated, you can link the task group to a specific assembly product within your aACE system. Whenever that product is added to an order, aACE auto-generates the task group as part of the production process.

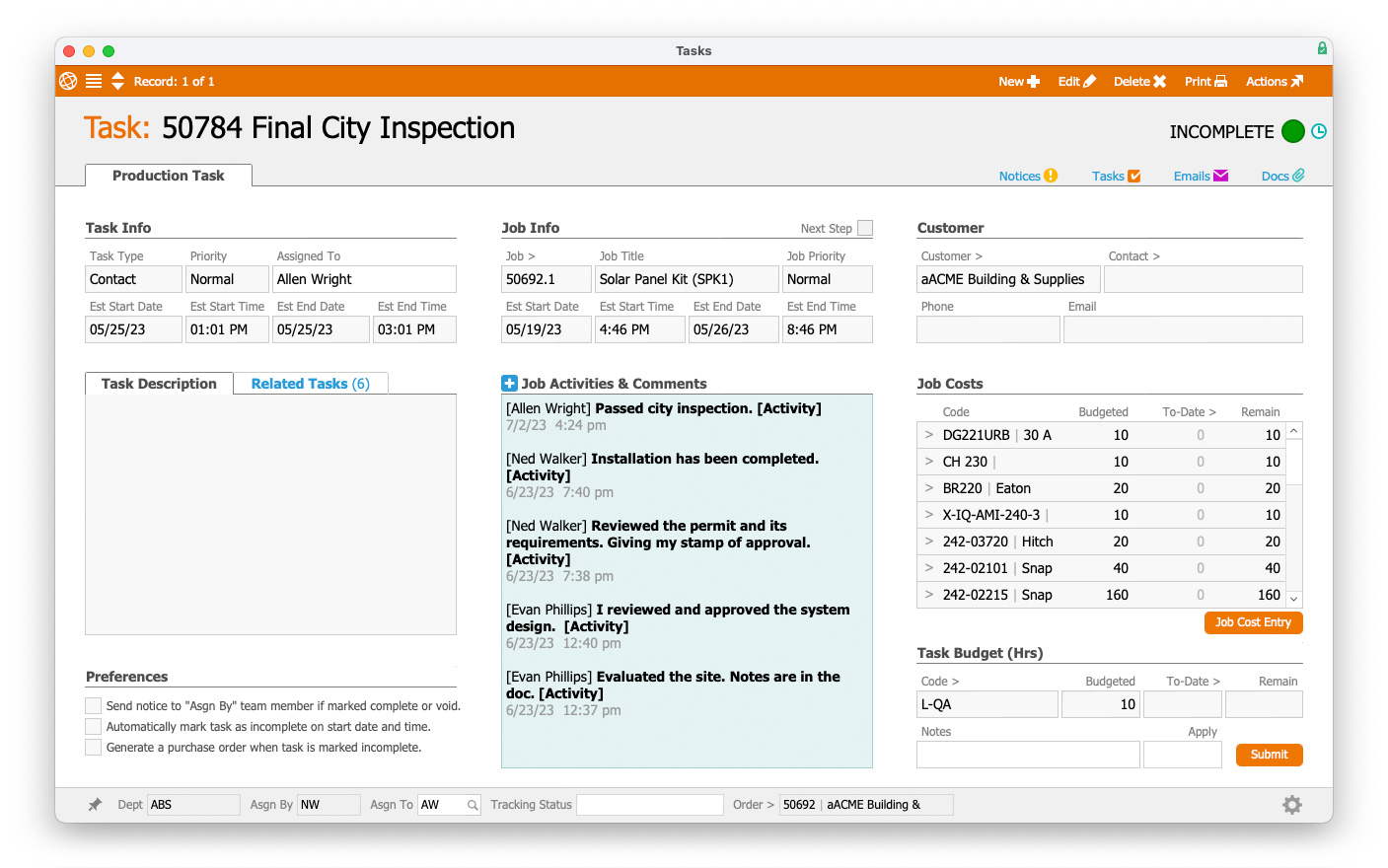

aACE also tracks the status of each of your task group’s tasks. Each task record has its own status, which can be changed depending on the task’s progress. These statuses include: pending, incomplete (in-progress), complete, or void. Team members can also include comments and activities on specific tasks to keep everyone updated on the progress.

aACE’s robust scheduling also tracks your task group’s timeline. If a task within your task group has been delayed or voided (removed), aACE automatically adjusts the timeline to keep your workflows organized and moving.

aACE in Action: Production Workflow

Suppose a business sells different educational student tablets. They also sell tablet bundles that include extra educational items and add-ons to the student tablets. These tablet bundles require assembly.

A team member within the business creates a new task group to streamline the tablet bundle assembly process. The team member adds four tasks to the task group and assigns them to the relevant department and production member. For each individual task, he also sets an estimated start and end date as well as a budget. He saves and activates the task group, then assigns it to the correct tablet bundle product in his aACE system.

The team member creates a new order. He adds the tablet bundle then saves and opens the order. aACE auto-generates the task group’s tasks on the order. This action notifies the production or warehouse team that they must assemble a new bundle. As the team moves through the tasks, they will enter new statuses and updates about the assembly process. A manager can then track the progress and timeline of the assembly item by viewing the related task records.

Utilizing task groups to manage repetitive workflows for your production or related processes is just one way aACE helps you run your business more efficiently. Read about how aACE Notices can help improve employee communication.